Last November, I heard about a Willcox & Gibbs treadle on the Salvation Army website. The treadle was in Santa Monica, California, and they didn't ship, it had to be a local pick-up. One of the ladies in one of my vintage sewing machine groups said that she lived an hour from there and would be happy to pick up the machine and hold it for me, so I went ahead and bid on the treadle.

Well, I bid on the treadle, and at the end, there was a bidding war between me and one other bidder. It was going up, $1 by $1 for a while, but, in the end, I won the auction for a whopping $32! Woohoo!

Nancy picked up the treadle a few days later, and when she got there, she discovered that the treadle drawers were full of goodies (not mentioned in the ad). Woohoo, even better! Nancy was drooling over the decals and the lovely attachments in the drawers (these seldom come with any of the attachments).

Well, Nancy held my treadle until Kim could pick it up. Kim drove it to Flagstaff, AZ, where Wendy held it until my nieces friend could pick it up and drive it to Albuquerque, NM, where it changed hands 3 more times, and then it headed to Silver City, NM, where Anne and Bob picked it up. After they picked up the treadle, it got to vacation with them across several states for the next 3 months before it finally got to their home in Wisconsin. Last Saturday, hubby and I drove up to Wisconsin to pick up the treadle (and eat some yummy venison with Anne & Bob).

This week, I've cleaned the treadle irons and the wood cabinet, and today I cleaned the sewing machine. The entire treadle is in great shape for a 109 year old machine. It was dirty, especially the treadle irons, which had some rust on them.

|

| before cleaning |

|

| before cleaning |

|

| lovely treadle peddle |

I cleaned the irons outside (in the 90+degree heat). You can see the rust on these 'before' photos.

|

| belt guard |

Here are the irons after cleaning and then waxing (Howard's Feed 'n Wax was used).

|

| belt guard |

|

| re-assembled |

One of the feet that holds the wheels on the treadle is broken. Nancy found 2 treadle wheels in one of the drawers. Since the metal foot is broken, there isn't a way to fix this (the broken part wasn't in the drawer). At least it is the back wheels that aren't on the treadle anymore, so it tilts a fraction of an inch backwards. Not a problem.

|

| Front wheels |

|

| back wheel (not broken) |

|

| back wheel, broken off |

Next was cleaning the wood on the cabinet, then waxing it (also with Howard's).

|

| before |

|

| before |

|

| after cleaning & waxing |

Today it was the machine's turn to get cleaned & polished. First, the before photos (it wasn't very dirty).

|

| before cleaning |

|

| before cleaning |

|

| Serial #A586194 (from 1913) |

|

| thread and lint in the looper |

|

| dirty hand wheel |

After cleaning the lint out and finding a whole bunch of thread wrapped around the hand wheel (I've not seen that before this machine)....

|

| lots of lint around the feed dogs |

|

| threads wrapped around the hand wheel |

|

| the thread I got off the hand wheel |

Finally, the treadle is re-assembled (except for the treadle belt, which will happen after I post this).

|

| 1913 Willcox & Gibbs treadle |

I did test it, and it sews nicely! This machine makes a chainstitch.

|

| stitching from the top |

|

| stitching showing the chainstitch underneath |

I told you that this treadle came with several attachments in the drawers. Here is what came with it.

|

| ruffler with original instruction sheet |

|

| original manual (109 years old) |

|

| Tuck Marker in original box |

|

| Wide, Narrow and Linen hemstitchers |

|

| wrench, gathering foot, quilt bar and seam guide |

Oh yes, and Anne gave me some original W&G needles from her Boye needle case (Thanks Anne)!

|

| 2 Boye needle cases for W&G's |

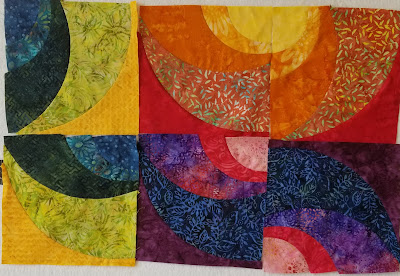

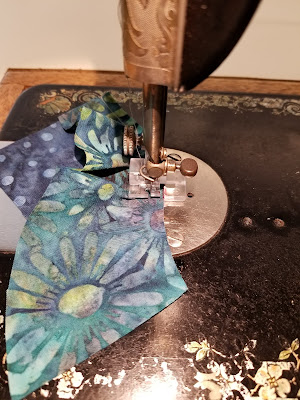

I have done some other things this week besides cleaning the treadle. My Treadle On group is having an Advanced block exchange using the

Radiant Sun's pattern (curved piecing). I was smart and bought the templates, not just the pattern. Those templates are worth every penny!

Earlier this year, I went thru my batiks and pulled fabrics, then bought the few colors that I didn't already have. This week, I cut the pieces I'll need for the 3 different colorways (24 blocks in one colorway, 12 blocks each in the other 2 colorways).

|

| 24 blocks worth cut |

|

| 12 blocks worth cut |

|

| 12 blocks worth cut |

Cara Gulati, who wrote the pattern, has a great YouTube video telling how to make this quilt from picking the fabrics thru stitching the blocks. Hopefully the curved piecing goes as well as the cutting did.

I have two different sew-in's next week, so I'll be prepping some things to work on for them. What are you working on this weekend?